Softwaresuite für kompakte NIR Spektrometer

Softwaresuite für kompakte NIR Spektrometer

Egal ob Identifikation unbekannter Stoffe, Analyse großer Datenmengen oder einfach das Erzeugen und Speichern von NIR Spektren im offen Datenformat: Die verschiedenen Softwaremodule unserer Softwaresuite decken die unterschiedlichsten Anwendungsfälle ab.

Am auffälligsten ist jedoch die konsequente Reduktion der Funktionen. Durch die Konzentration auf das Wesentliche gelingt rasch der Einstieg, auch Laien. Die verschiedenen Darstellungsformen (Rohspektren & Clusterdarstellung) lassen den Anwender schnell die Funktionsweise der Software und die Zusammenhänge in den Daten verstehen. Das offene Datenformat bringt einen einfachen und gut verständlichen Umgang mit den Daten und freie Bearbeitung: Perfekt für den Einstieg in die Nahinfrarotspektroskopie!

Übersicht verfügbare Module

- Recorder – Das Basismodul. Für das Erstellen, Visualisieren und Speichern einzelner Spektren.

- Player – Die Voraussetzung für alles Weitere, ganz egal ob es sich um unsere Standardanwendung für das Analysieren von Daten oder fertig entwickelte Anwendungen handelt. Der Player spielt alle Anwendungen ab und verarbeitet die Daten wie gewünscht.

- Wir bieten Standardanwendungen für

- die Analyse von Daten,

- die Kunststoffidentifikation und

- die quantitative Beurteilung der NIR Detektierbarkeit.

- Darüber hinaus können wir beliebig komplexe, individuelle Anwendungen für sie entwickeln.

- Wir bieten Standardanwendungen für

- Data Manager – Damit analysieren Sie Ihre Daten, unter anderem mit Machine Learning Methoden, und lernen neue Daten ein, sofern die Anwendung das unterstützt.

Recorder

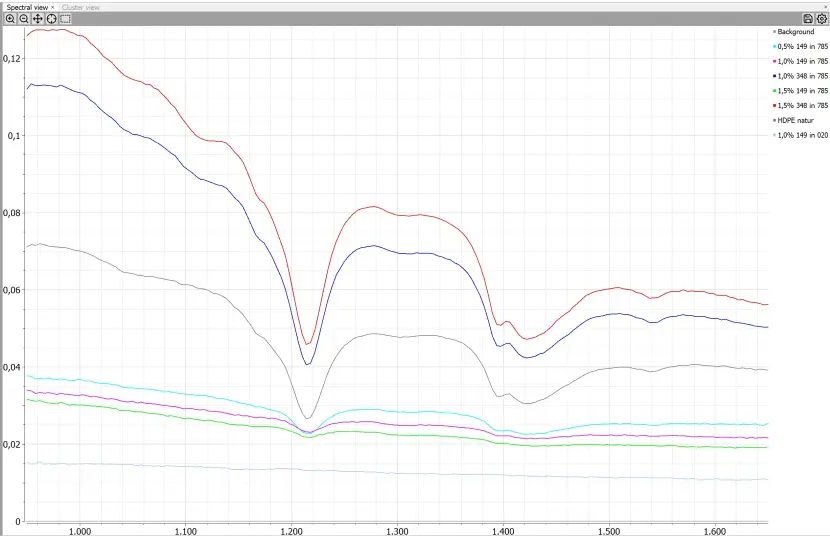

Das Softwaremodul stellt die bearbeiteten Messdaten als Rohspektrum dar. Der Wellenlängenbereich reicht von 900 nm bis 1.700 nm.

Visualisierung

Die durch den Scanner erzeugten Daten werden weder gefiltert noch geglättet, d.h. sie erhalten die rohen Daten. Das Grundmodul ist Teil des Lieferumfangs des Solid Scanner.

Entsprechend ausgebildete Mitarbeiter können innerhalb einer Sekunde mit der eigenen Interpretation des gemessenen Spektrums beginnen. Die qualitative Bewertung des Spektrums ist damit möglich. „Gute“ von „schlechten“ NIR Spektren zu unterscheiden gelingt sofort. Mitarbeiter ohne Expertenwissen bestimmen mit Hilfe der optional erhältlichen Anwendungen schnell und sicher Kunststoffe.

Technische Spezifikation

- Mehrsprachigkeit (Deutsch und Englisch)

- Betriebssystem ab Windows 7 und Mac. Linux auf Anfrage

- Datenimport und -export mittels JCAMP (

.jdx, .dx; Joint Committee on Atomic and Molecular Physical Data)

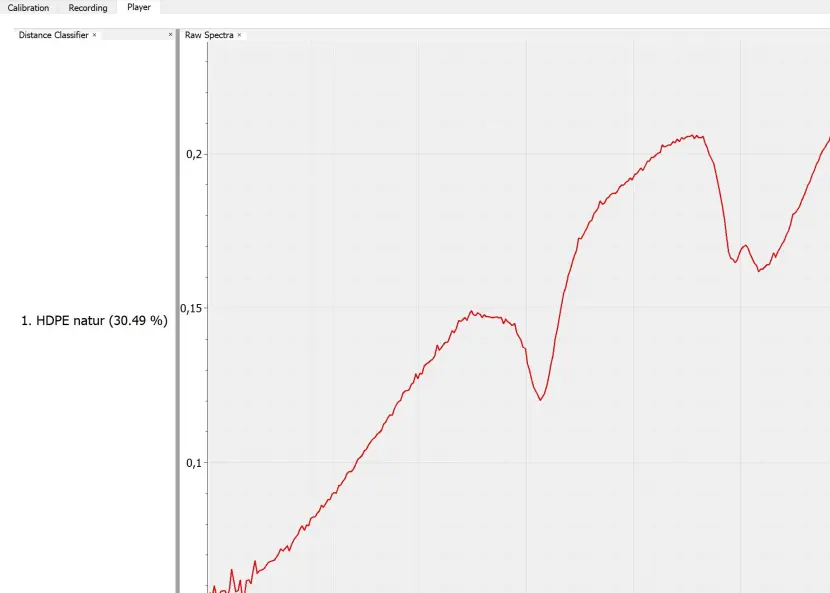

Player

Der Player ist ein mächtiges Tool. Er spielt alle von uns zur Verfügung gestellten Anwendungen ab. Dabei können wir auf einen umfangreichen Werkzeugkasten für die Entwicklung zurückgreifen.

Unsere Standardanwendungen:

- Standardanalyse

- Kunststoffidentifikation

- NIR Detektierbarkeit

Unsere individuellen Anwendungen:

Hier gehen wir individuell auf ihre Aufgabe ein, ganz egal ob es sich dabei um eine Abwandlung einer Standardanwendung oder eine komplett neu entwickelte Anwendung exakt passend für Ihre Situation handelt: Sprechen Sie uns an!

… wir freuen uns, Sie mit unserer Expertise unterstützen zu können.

Data Manager

Standardanalyse: Hier können klar 3 Gruppen unterschieden werden: Blau/Türkis, Rot & Grün. Die Messungen in Gelb zeigen eine zu hohe Streuung und können in dieser Anwendung nicht sinnvoll als Gruppe eingelernt werden.

Der Data Manager hilft ihnen neue Daten zu analysieren und die Daten der Anwendungen zu ändern, falls verfügbar. Konkrete Beispiele:

- Standardanalyse: Mit dem Data Manager gruppieren Sie Spektren und lassen sich dann die durchschnittlichen Spektren dieser Gruppen anzeigen. In der Clusteransicht suchen Sie mit Hilfe einer Hauptkomponentenanalyse Zusammenhänge in großen Datenmengen. Sie erkennen homogene wie inhomogene Materialien und können passende Spektren als einzelne Gruppen einlernen. Damit erstellen Sie Ihre eigene Anwendung z.B. für den Wareneingang.

- Kunststoffidentifikation: Diese Anwendung beinhaltet bereits einige Kunststoffe. Wollen Sie die Zusammensetzung der Datenbank ändern, können sie ähnlich der Standardanalyse vorhandene wie neue Daten analysieren und ihre Datenbank entsprechen aktualisieren. Darüber hinaus empfiehlt sich hier ein Abo für diese Anwendung, um immer auf dem neuesten Stand zu bleiben.

- NIR Detektierbarkeit: Diese Anwendung beinhaltet als Referenzen PP und PE Kunststoffe. Für eigene Referenzen tauschen Sie die vorhanden mit ihren Messungen aus und aktualisieren anschließend die Anwendung.